Description

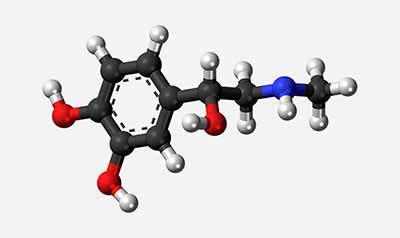

Lead and lead alloy anodes are used in the electroplating process to alter the chemical and physical properties of metallic surfaces, depending on the application for which they are destined. For example, these types of lead anodes are commonly used in the chrome plating process, increasing the hardness of an object, or piece of equipment, thereby improving resistance to corrosion and preventing premature wear.

Canada Metal offers a wide range of high quality, non-sacrificial lead and lead alloy electroplating anodes, for light and heavy duty requirements. An area of expertise for us, we custom manufacture to client specifications, using only high purity metals of consistent quality. Contact the professionals at Canada Metal North America to discuss your needs.

Applications

Electroplating processes including chrome-plated oil pump auger flights, hydraulic cylinders, conveyor flights, sheets and tanks.

Industries

Electroplating, hydraulics, manufacturing.

Formats

- Basket

- Grid

- Cored stick

- Stick

- Plate