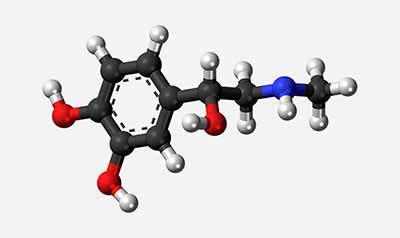

Description

Canada Metal supplies a complete range of lead and tin-based Babbitt metal, including our trade-mark Harris Heavy Pressure, ideal for slower speed work and less heavily loaded bearings. Depending on a variety of factors, including surface speed of the shaft, load-bearing and cooling facilities, we will help you to select the Babbitt metal that is custom fit to your requirements.

Babbitts available are ASTM B 23-00 (2005), grades #1, 2, 3, 11, 7, 8, 13, 15.

Babbitt Metal: Essential Solutions for Bearing Repair

Reliable Babbitt Bearing Repair Services

At Canada Metal, we specialize in high-quality Babbitt metal, ideal for Babbitting applications and effective Babbitt bearing repair. Our Babbitt metal products are designed to provide exceptional performance and longevity in various industrial settings. Whether you’re looking to repair existing bearings or create new ones, our materials ensure optimal durability and reliability.

With our expertise in babbitting, Canada Metal stands out as a trusted North American manufacturer. Our Babbitt metal is formulated to withstand wear and tear, providing a seamless solution for your bearing needs. Don’t compromise on quality; choose Canada Metal for all your Babbitt metal requirements.

Get in touch with us today to get more details about our Babbitt metal offerings and how we can assist with your Babbitt bearing repair needs!

Applications

Gas Turbines, Hydraulic Turbines, Compressors, Electric motors, Gear drives, Pumps, Bearings, Ball Mills, Rod Mills, Sag Mills

Industries

Power generation, Mining, Heavy Equipment

Formats

Standard formats are 1 1b bar, 5 lb bar or cake and 10 lb notch bar.

Custom formats available on request.