Lead Bricks

Description

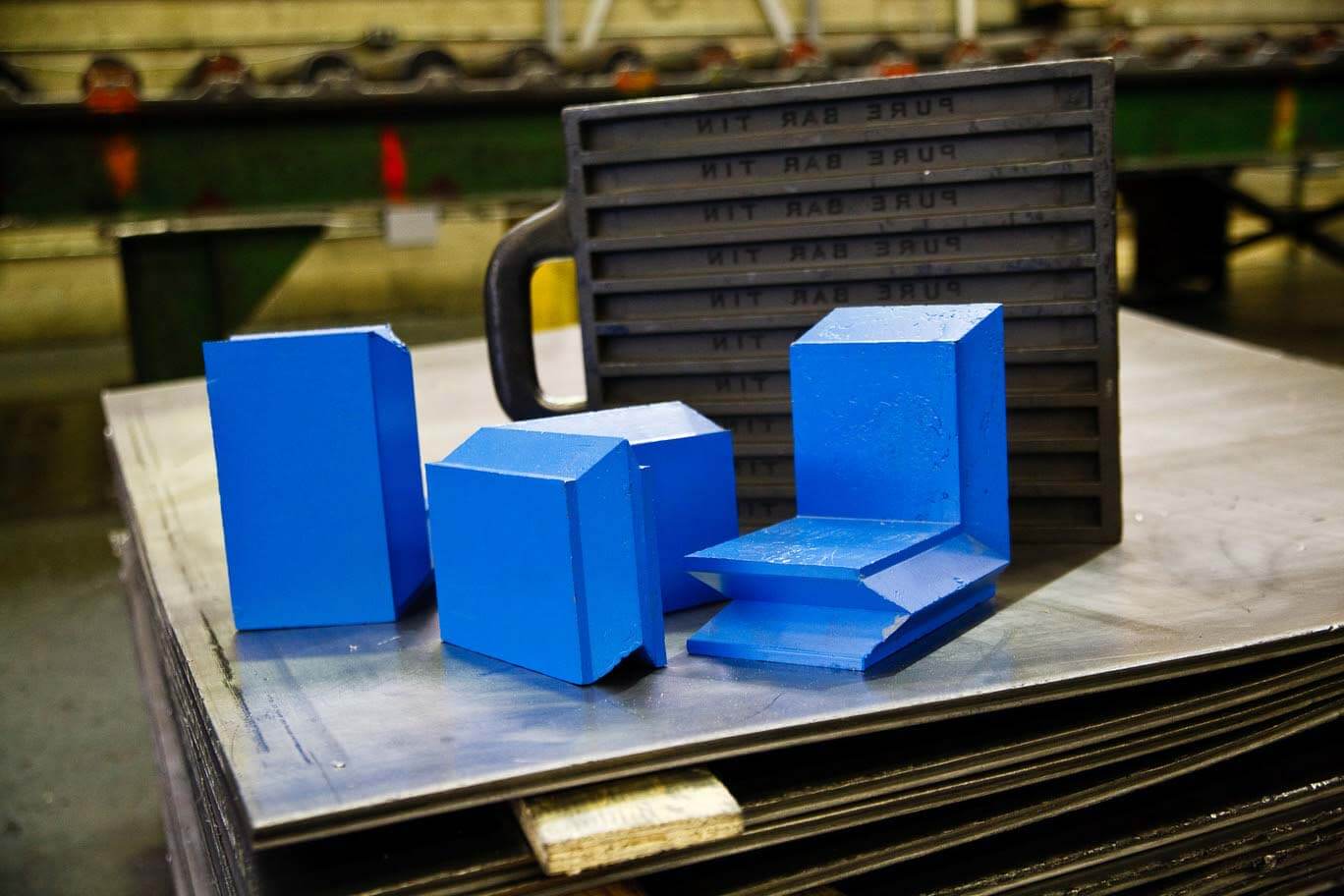

Canada Metal’s lead blocks and cast lead & extruded bricks offer maximum protection against x-ray radiation. Lead bricks can be manufactured to specification and include chevron-style, interlocking straight and corner bricks. Lead blocks are available in inventory in flat and interlocking “V” formats in a variety of weights and sizes, and can also be manufactured to specification.

Lead bricks are used to block the effects of radiation. Canada Metal’s bricks are designed to fit together easily, enabling contractors and building managers to create a custom lead wall or surface. These interlocking bricks feature a flat surface with a “V” profile that can be easily combined for a secure, solid, leak-proof barrier.

Interlocking lead bricks are specified by architects and engineers in the construction, healthcare and nuclear industries. Many hospitals, medical and research laboratories, and facilities with sources of radiation such as X-ray equipment, or radioactive isotopes, will use these bricks for effective shielding.

Consult the experienced professionals at Canada Metal to discuss specific project needs.

Applications

Industries

Formats

Standard sizes available, plus Corner Bricks and Blocks in the following sizes:

| Interlocking “V” | Size (inches) | Size (mm) | Approx. Weight |

| Std. Corner | 2 x 4 x 5 | 50.8 x 101.6 x127.0 | 23 lbs (10.4 kg) |

| Top Corner | 2 x 3 x 5 | 50.8 x 76.2 x 127.0 | 17 lbs (7.8 kg) |

| Base Corner | 2 x 3 x 5 | 50.8 x 76.2 x 127.0 | 17 lbs (7.8 kg) |

Frequently Asked Questions

What are lead bricks used for?

Lead bricks are primarily used for radiation shielding in medical, nuclear, and industrial environments. They are ideal for constructing protective barriers, walls, and enclosures where exposure to radiation needs to be minimized. Their inherently scalable nature means lead bricks can be the ideal solution for a large room requiring thousands or a small lead “castle” for use in research applications. Canada Metal will work with you to develop exactly what you need.

What are interlocking lead bricks?

Interlocking lead bricks typically feature a chevroned design that allows them to securely fit together to ensure there is no radiation penetration. This design also ensures better stability and alignment, making them ideal for creating modular shielding systems.

Are lead bricks customizable for different applications?

Yes, lead bricks are available in a variety of sizes, shapes, and thicknesses. Custom fabrication options are also available to meet specific shielding requirements or architectural constraints.

Do interlocking lead bricks offer better radiation protection?

Yes, interlocking lead bricks provide enhanced radiation shielding because their overlapping design reduces the risk of gaps and misalignment. This ensures a more effective and seamless barrier.

Can I use lead bricks for temporary or mobile shielding?

Absolutely. Both standard and interlocking lead bricks are suitable for temporary shielding setups, such as mobile medical units or portable labs, due to their modular and stackable nature. However, straight edge bricks should only be used for radiation protection if they’re appropriately layered. Ensure you consult with a specialist when designing radiation protection equipment.

Are your lead bricks compliant with safety standards?

When used appropriately and with proper PPE, lead is safe. Depending on your use-case, Canada Metal will be happy to work with you to develop options, such as special coatings, that make our lead brick safe to handle.

How do I choose between standard and interlocking lead bricks?

Always consult with a properly certified expert or building codes for radiation protection designs. Canada Metal is happy to work with you and your team to determine what you need.

How heavy are lead bricks?

Lead bricks are very dense, and their weight can vary based on dimensions. On average, a standard lead brick can weigh between 20 to 60 pounds. Canada Metal can advise on weight specifications and handling best practices.

Comments or questions are welcome.